Product Introduction

ristar high efficiency multi-cyclone gas/liquid/solid separator is a high capacity separator designed for removing liquids and/or solids from gas flows with a minimum of pressure drop. It is self-cleaning, requires no scrubbing liquid. It can handle relatively large quantities of entrainment and needs only periodic blowdown for removal of collected material. It is highly efficient over a wide range of operating conditions and can be designed in either the vertical or horizontal configuration.

The separator utilizes American advanced multi-cyclone technology, widely uses on large flow rate gas/liquid/solid separation in the area of coal chemical, petrochemical, chemical, oil refinery etc., especially in the field of coal chemical industry has a wide range of applications.

Performance Guarantee

- 100% liquid particle separation 8 microns and larger;

- 100% solid particle separation 5 microns and larger;

- Liquid carryover from the outlet gas will be less than 0.01kg/1,000Nm3;

- Pressure drop through the complete separator will be less than 15 kpa.

Application Examples

- Shenhua Ningmei coal to methanol revamping project;

- Petrochina Pengzhou oil refinery project;

- Zhejiang Petrochemical 40 MTPY refinery integration project;

- Petrochina East West gas pipeline project phase II;

- Nidonesia PT. Yerry Primatama Hosindo Multi-cyclone project.

Technical Advantages

- Large flow is split into different cyclone tube which reduces the amount of flow in each factor hence increasing the entry speed, increase centrifugal force and separator efficiency;

- Able to simultaneously separate the liquid and solid in the gas to achieve satisfactory separation results;

- Different cyclone tube sizing and layout will reduce the equipment dimensions and cost saving;

- Using different designs to solve the issue of operating flow ratio problem that utilizes centrifugal principle;

- Different separator parts design resolves the difficulties of separating large amounts of liquid and solids in the gas.

Working Principle

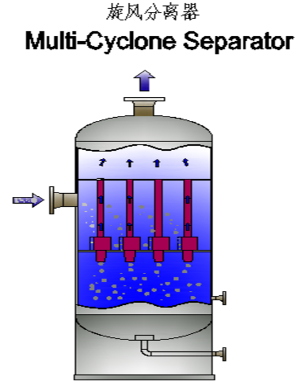

The principle of multi-cyclone separator is based on centrifugal force mechanism . Contaminated gas enters the distribution chamber of the scrubber which contains a multiplicity of small cyclone tubes arranged in parallel. The gas stream enters each of the tubes through two tangential openings. Producing a rotating and outward driving force removing particulate matter from the gas. This centrifugal action keeps the particulate matter at the outer periphery of the ratating mass where it continues downward to the collection chamber at the bottom of the vessel. The cleaned gas reverses its flow at the vortex of the cyclone tube , moves upward through the riser and into the exit plenum.